STEEL REINFORCEMENT

(a) Its tensile strength is high

(b) It can develop good bond with concrete.

(c) In coefficient of expansion is nearly same as for concrete.

(d) It is easily available.

SIGNIFICANCE FUNCTIONS OF REINFORCEMENT IN R.C.C

The reinforcement in RCC serves the following different types of functions.

(1) To resist the bending tension in flexural members like slabs, beams and walls of water tanks etc.

(ii) To increase the load carrying capacity of compression members like columns

(iii) To resist diagonal tension due to shear

(iv) To resist the effects of secondary stresses like temperature etc.

(v) To reduce the shrinkage of concrete.

(vi) To resist spiral cracking due to torsion.

(vii) To prevent the development of wide cracks in concrete due to tensile strains.

TYPES OF REINFORCEMENT

The following four types of steel reinforcement are generally used in reinforced concrete construction.

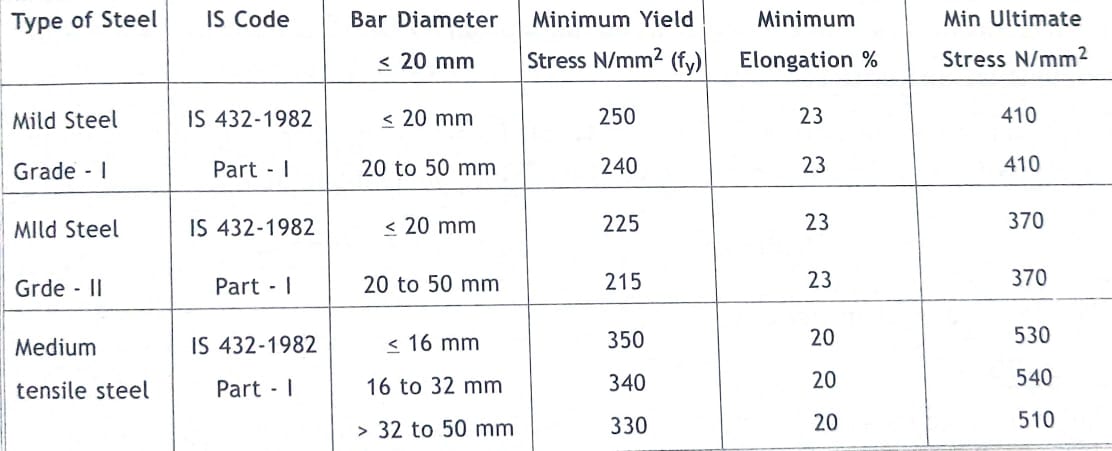

(a) Mild steel and medium tensile steel bars conforming to IS: 432 (Part-1)

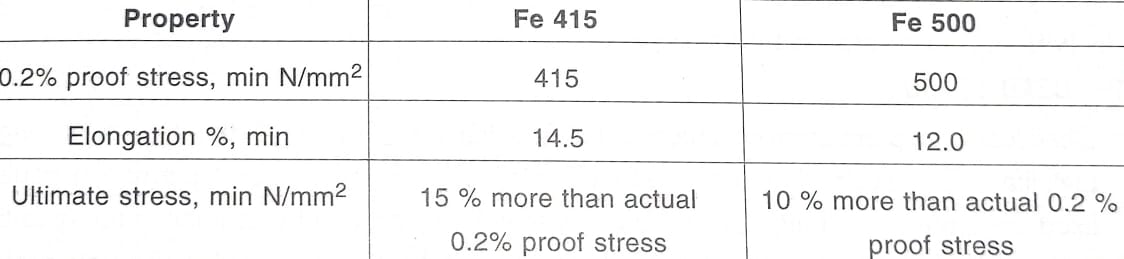

(b) High yield strength deformed steel bars (HYSD bars) conforming to IS: 1786

(c) Steel wire fabric conforming to IS: 1566.

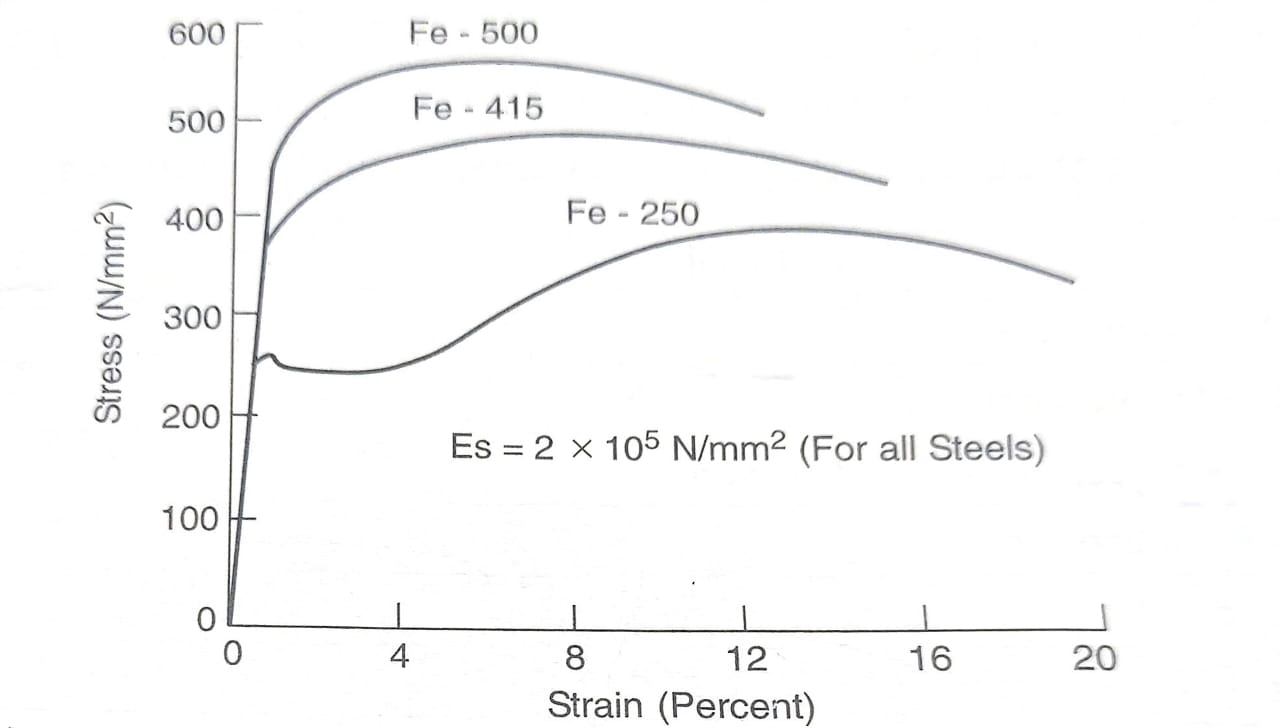

All reinforcement shall be free from loose mill scale, loose rust, oil, mud, and any other substances which reduces bond between steel and concrete. The grades of steel normally used for reinforcement are Fe 250, Fe 415 and Fe 500. In mentioning the grade of steel, Fe refers to ferrous metal and the number following it refers to specified guaranteed yield strength in N/mm². The stress strain curves for different grades of steel are shown in Fig

Typical stress-strain curves for Reinforcing Steel

Mild Steel Bars (Fe 250): These plain bars of mild steel are of grade Fe 250 conforming to IS: 432-1982. It has well defined yield point giving yield stress of 250 N/mm² and excellent ductility with high percentage of elongation at failure (> 23%). The actual and idealized stress strain curve for mild steel is shown in Fig . The properties of mild steel are given in Table

Properties of mild steel

High Yield Strength Deformed Bars (Fe 415 & Fe 500): As the name indicates, these HYSD bars have high yield strength but the yield point is not well defined. The yield stress or characteristic stress is given by 0.2% proof stress. These bars possess ribs, lugs or deformations on their surface due to which the bond strength is improved. The properties of HYSD bars are given in Table

Properties of HYSD BARS