EQUIPMENT USED FOR CHAIN SURVEYING

The following equipments are used for chain surveying

(a) Metric chain (20 or 30 m)

(b) Arrows

(c) Metallic tape

(d) Ranging rods

(e) Offset rod

(f) Cross-staff or Optical square

(g) Plumb-bob

(h) Wooden pegs

(i) Mallet

(J) Field book

(k) Pencils, Eraser, Knife etc.,

CHAIN

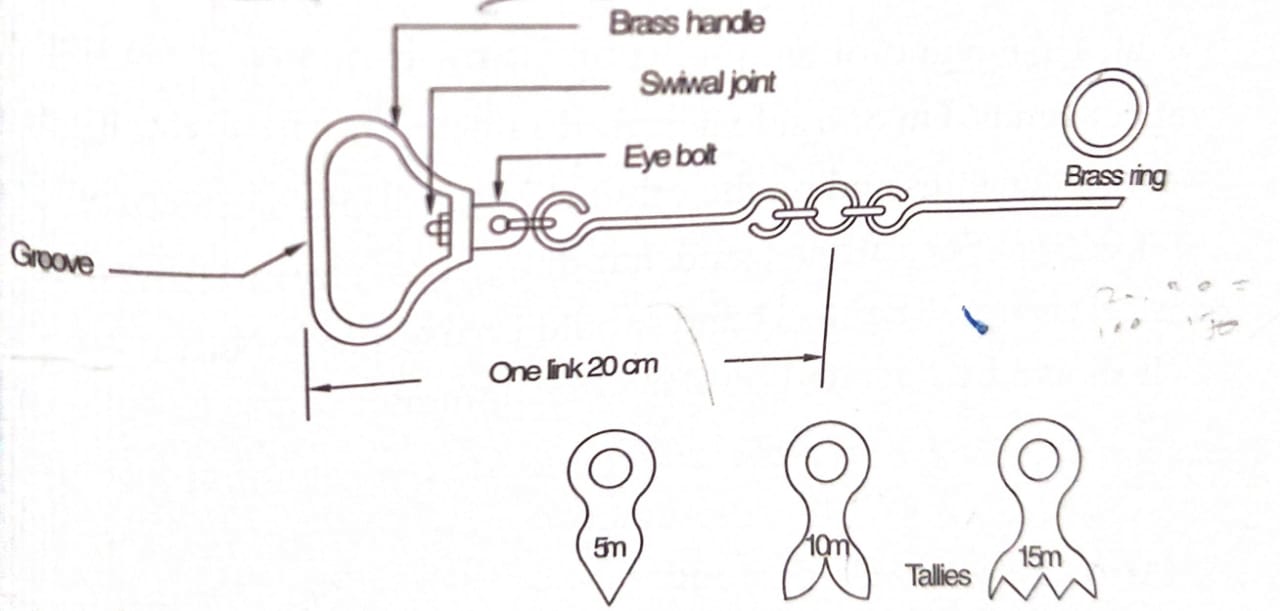

Chains are prepared of galvanised mild steel wire straight links bent into rings at the ends and joined each other by three small circular or oval wire rings. The ends of the chain are provided with brass handle at each end with swivel joint, so that the chain can be turned without twisting.. The length of the chain is, outside of one handle to the outside of the other handle

The following are the various types of chains, in common use

(1) Metric chain

(ii) Gunter’s chain or surveyor’s chain

(iii) Engineer’s chain

(iv) Revenue chain

(v) Steel band or band chain

1. Metric Chain: Metric chains are available in lengts of 5, 10, 20 and 30 metres. Among the 20 m and 30 m are commonly used. 20 m chain is divided into 100 links and 30 m chain is divided into 150 links. Length of each link is 0.2 m. The brass tallies are fixed at every 5m length and small brass rings are provided at every metre length. The least count of the metric chain is 0.2 m or 20 cm.

2, Gunter’s Chain or Surveyor’s Chain: This chain is 66 feet long and having 100 links. So, each is of 0.66 ft. It is very useful for measuring the distances in miles and furlongs. It is also useful for measuring the area in acres.

1 Gunter’s chain = 22 yards

10 Gunter’s chains = 1 furlong

80 Gunter’s chains = 1 mile

1square guntur chains= 1mile

10 Square gunter chains = 1 Acre 4840 sq yards (100 cents)

3. Engineer’s Chain: The engineer’s chain is 100 ft long and divided into 100 links. So, length of each link is of 1 foot Tallies or tags are provided at every 10 links (10 ft.), the central tally being round. Engineer’s chain was previously used for all engineering works.

4. Revenue Chain: This chain is 33 ft. long and divided into 16 links. Length of each link being 2 ft 0.75 inches. It is commonly links used for measuring fields in cadestral surveys and also used by the revenue department for measuring land in bighas. One square Revenue chain equal to one bigha

5. Steel Band or Band Chain: It consists of a ribbon of steel of width 16 mm and of length 20 or 30 m. It has a brass handle at both ends. On one side it is graduated in metres, decimetres and centimetres and on the other side graduation are provided at 0.2 m. For carrying and handling it is wound on special steel crossgs. The steel band should be used for accurate work It should be operated by skilled chainmen

ARROWS:

Arrows are made of good quality hardened and tempered steel wire of diameter 4 mm. The overall length of the arrow may be 400 mm . one end of the arrow is bent into a ring of 50 mm. diametre and other end is made sharp pointed, Arrows are used for counting the number of chains completed, while measuring a chain line. Generally 10 arrows are supplied with a chain

TAPES:

Tapes are used to take more accurate measurements. They are classified according to the material of which they are made.

(i) Cloth or linen tape

(ii) Metallic tape

(iii) Steel tape and

(iv) Invar tape

1. Cloth or Linen Tape: It is a tape made of closely woven linen and is varnished to resist moisture. It is 12 to 15 mm wide and available in lengths of 10, 20 and 30 metres. This tape is generally used for measuring offsets and for ordinary works.

2. Metallic Tape: If a linen tape is reinforced with brass, copper or bronze wires to make it durable, then it is called a metallic tape. In this tape the wires are provided to avoid stretching. These tapes are available in lengths of 2, 5, 10, 20 and 30 m. These tapes are wound in a leather or metal case fitted with a winding device. It is commonly used for all the surveying works.

3. Steel Tape: The steel tape is made of steel ribbon of width varying from 6 to 16 mm wide. These tapes are available in lengths of 1, 2, 5, 10, 20, 30 and 50 m. It is graduated in metres, decimetres, centimetres and millimetres. The length of the tape includes the metal ring provided at the beginning of the tape. It is wounded in a metal case with a winding device. Steel tape is delicate and very light, therefore it cannot withstand for taking field measurements, but it can be used for standardising chain and for measurements in construction works.

4. Invar Tape: It is made of an alloy of steel (64%) and nickel. (36%). Its coefficient of thermal expansion is very low, hence It is not affected by change in temperature. These are 6 mm. wide and available in length of 30, 50 and 100 m. It is costly and very delicate, hence it is not used for ordinary work. It is used at places, where highest precision is required, like triangulation survey conducted by survey of India Department.

RANGING RODS:

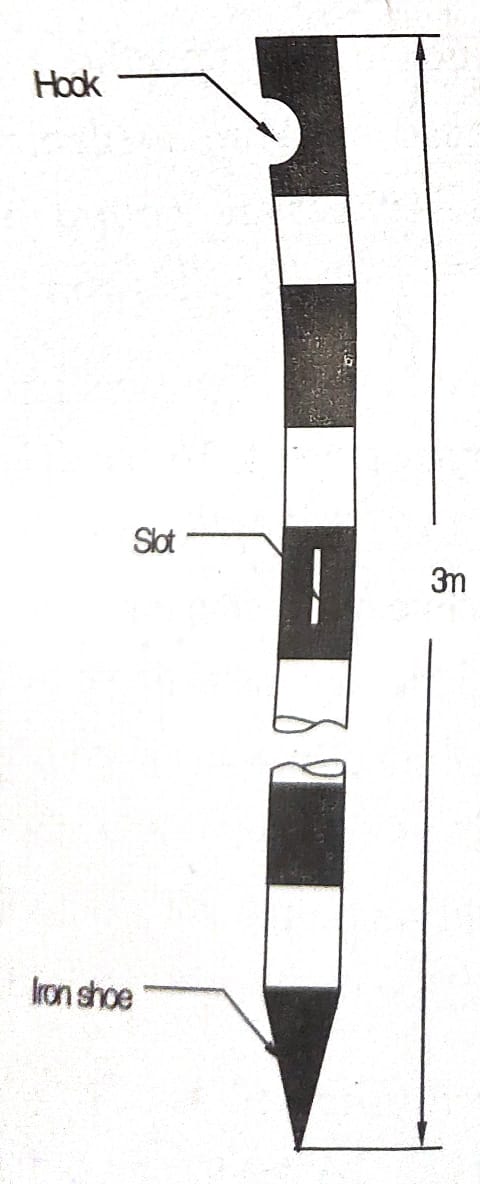

Ranging rods are circular or octagonal in cross section of 30 mm diametre and having a length of 2 or 3 m. They may be made either by wood or by steel tube, having sharp iron shoe at the bottom. The rod is divided into equal parts of 20 cm each and the divisions are painted black, red and white in successively This painting is done to make ranging rods visible for a long distance, about 200 m. Ranging rods are used for locating station points and for ranging B.e., the process of making a line straight) a survey line. Occasionally the ranging rod can be used for rough measurement of short lengths

OFFSET RODS:

An offset rod is similar to a ranging rod and has a length of 3m. The graduations are marked along the lengthwise in metres, decimetres, and centimetres. Generally they are round wooden rods, having a iron shoe at bottom and a notch or hook at the top. The hook facilitates pulling and pushing the chain through bushes or hedges. At eye level, two narrow slots are provided perpendicular to each other, to set right angles or for aligning the offset line. It is mainly used for measuring rough offsets near to the chain line.

CROSS-STAFF OR OPTICAL SQUARE:

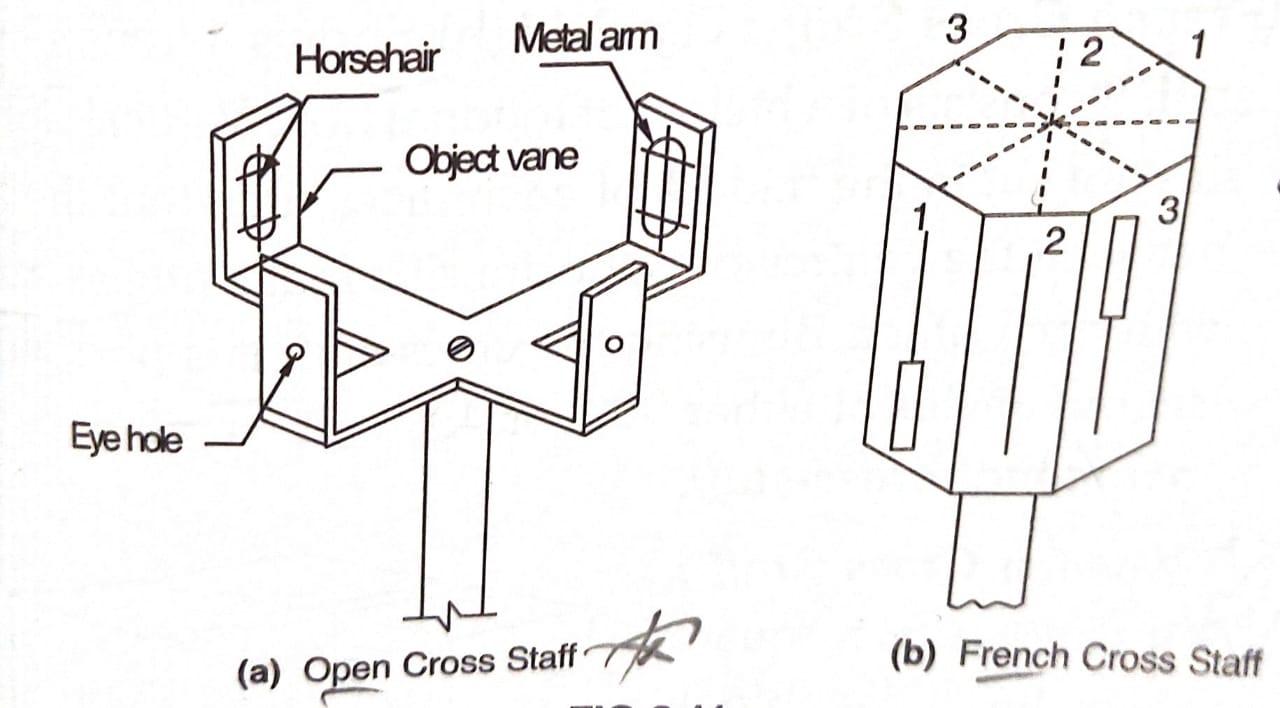

1. Cross Staff: The cross-staff is a simple instrument used for setting -out right angles. It consists of either a frame or box with two pairs of vertical slits and is mounted on a iron pole shoed for fixing into the ground. There are two types of cross staff.

(a) Open Cross Staff: Open cross staff consists of four metal arms at right angles to each other having eye vane at two adjacent sides and object vane at the others. Eye vane is provided with a pin hole or a narrow slit. In object vane a slit is provided with a horse hair at the middle. The line joining the eye hole and horse hair of one arm will be perpendicular to the eye hole and horse hair of the other arm.

Setting Right Angle with Open Cross Staff:

The cross staff is set up at a point on the line from which the right angle is to run, and it is then turned until one line of sight passes through the ranging rod at the end of the survey line. The line of sight through the other two vanes will be a line at right angles to the survey line and the ranging rods may be established in that direction.In case, it is to be used to set perpendicular offsets, it is held vertically on the chain line at a point where the foor of the offset is likely to occur. It is then rotated, so that one line of sight passes through the ranging rod fixed at the end of survey line. Looking through the other arm, it is seen if the point to which the offset is to be taken is bisected, if not, the cross-staff is moved forward or backward, along the chain line.

(b) French Cross Staff: Fig. 2.11(b) Shows a french cross staff. It consists of a hallow octogonal box. Vertical sighting slits are cut in the middle of each lace, such that the lines between the centres of opposite slits make angles of 45 with each other. By using the cross-staff it is possible, to set out angles of either 90° or 45. It is also called octogonal cross-stoff.

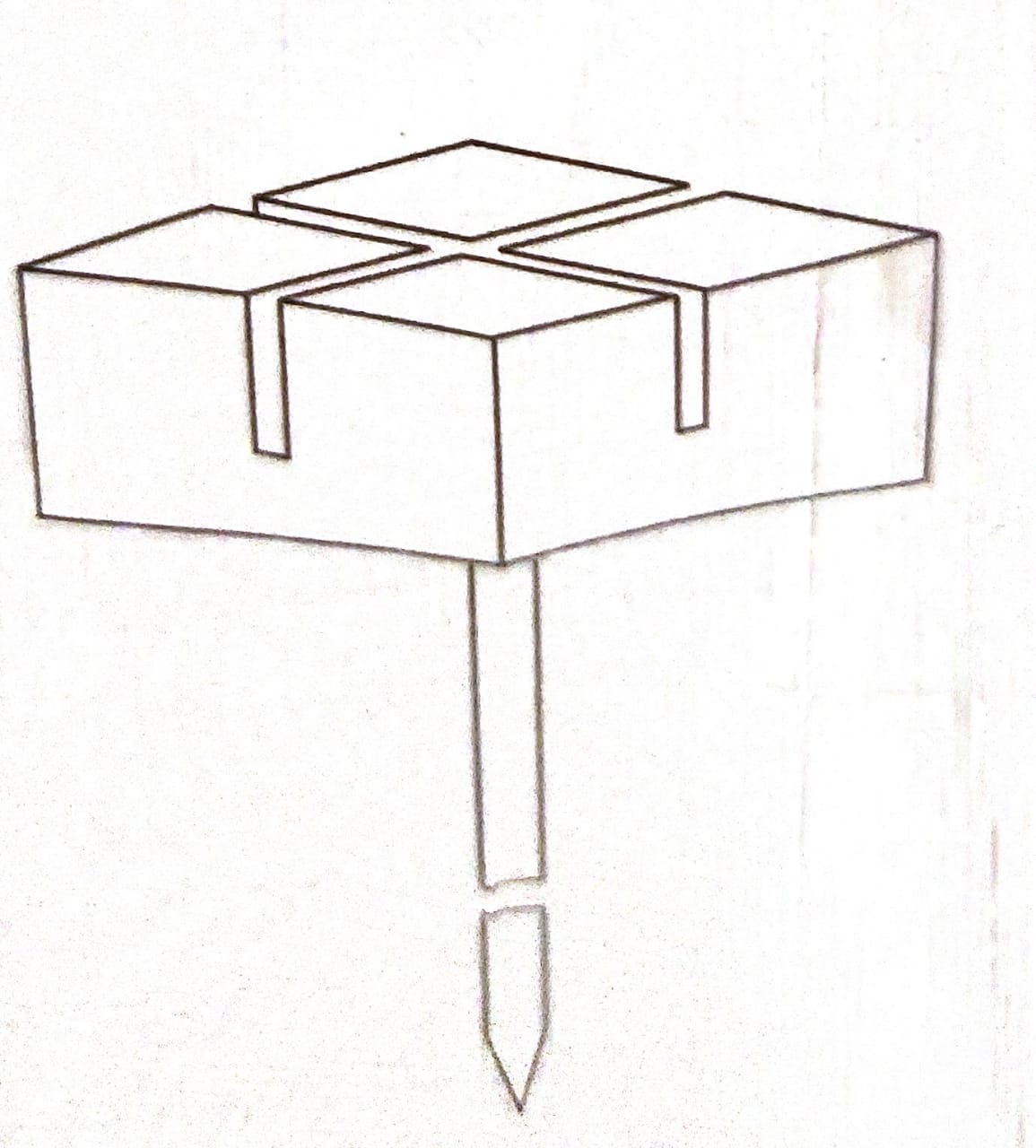

(c) Wooden Cross Staff: It consists of a square wooden block mounted on a iron pole having a sharp edge at the bottom For the wooden block grooves are cut upto the half thickness in perpendicular directions

OPTICAL SQUARE:

Optical Square: An optical square can also be used for setting but tight angles It consists of a small circular metal box of ametre 50 mm and depth 12.5 mm. It’s a metal cover which slides round the box to cover the slits

(a) A horizon glass ‘H’ is fixed at the bottom of the metal box. The lower half of the glass is unsilvered and the upper half is silvered.

(b) An index glass ‘T’ is fixed at the bottom of the box which is completely silvered.

(c) The horizontal angle between the index glass and horizon glass is set at 45°.

(d) The opening ‘e’ is a pin hole for eye E, ‘b’ is a small rectangular hole for ranging rod B. ‘p’ is a large rectangular hole for object ‘P’.

e) The line EB is known as horizon sight and IP as Index sight.

(f) The ray of light from ‘p’ is first reflected from ‘I’, then it is further reflected from H, after which it ultimately reaches the eye ‘E’.

PRINCIPLE

As per the principle of reflecting surfaces, the angle between the first reflected ray to the last reflected ray is twice the angle between the mirrors. In this case, the angle between the mirrors is 45°. Hence, the angle between the horizon sight and Index sight will be 90°

SETTING-OUT THE PERPENDICULAR WITH OPTICAL SQUARE:

1. The observer should stand on the chain line where the perpendicular is to be setup, approximately.

2. The optical square is held in the arm at the eye level. The ranging rod at the forward station ‘B’ is observed through the unsilvered portion on the lower part of the horizontal glass.

3. Consecutively observe the upper silvered portion of the horizon glass to see the image of the object ‘P’.

4. If the observer finds that the ranging rod ‘B’ and the image of object ‘P’ do not coincide. Then the observer should move forward or backward along the chain line until ranging rod ‘B’ and the image of ‘P’ exactly coincide (Fig. (b) & (c)).

5. At the position of the observer marks at a point on the ground to locate the foot is perpendicular.

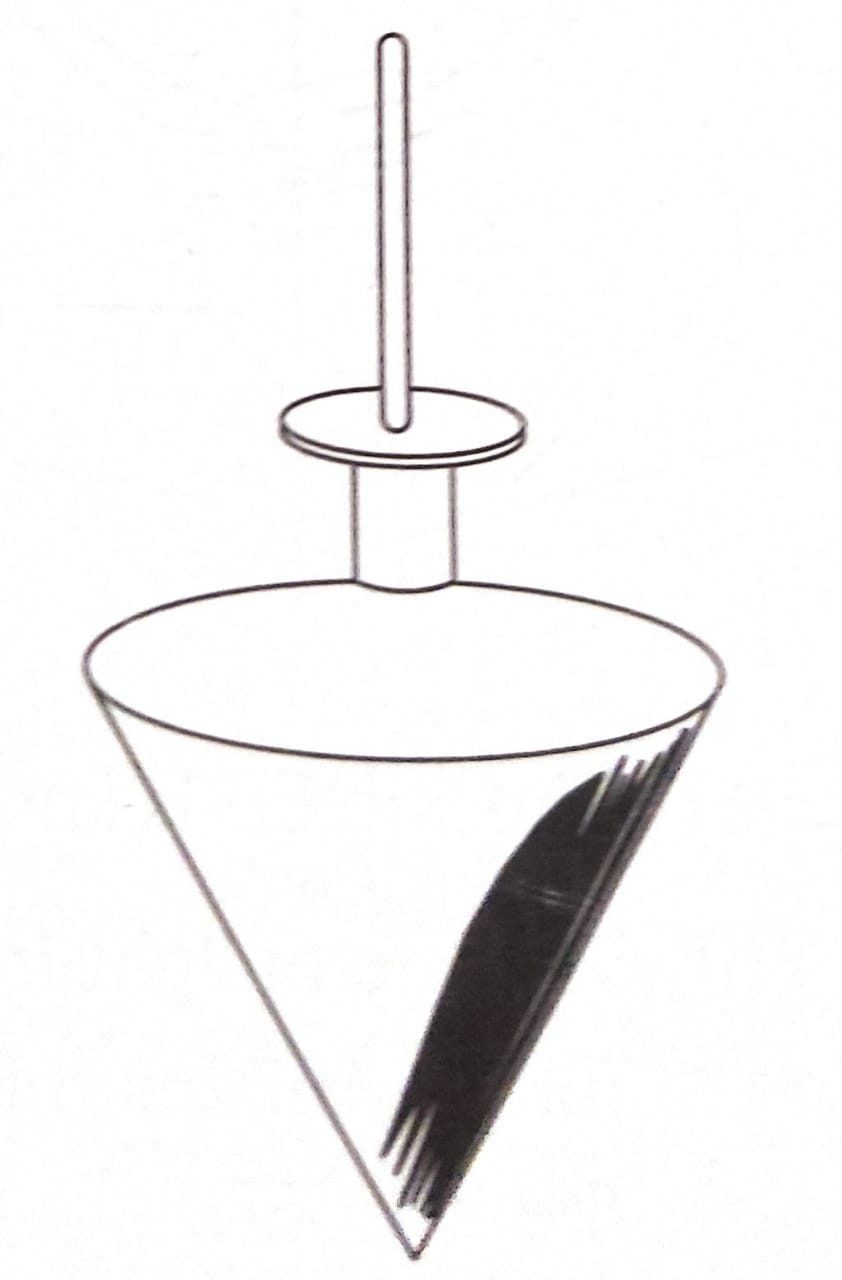

PLUMB-BOB:

While chaining along sloping ground, by the method of stepping a plumb – bob is required to transfer the points on to the ground. It is used to check the verticality of ranging rods and to transfer points from a line ranger or optical square. It is also used for centering of the surveying instruments such as compass, theodolite, tacheometer and plane-table. It is generally made -up of Iron or Brass.

WOODEN-PEGS:

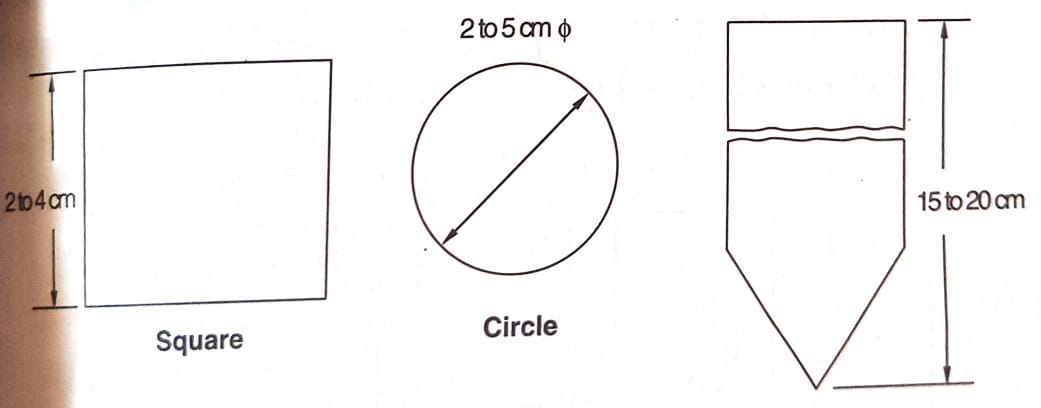

The wooden-pegs are used to marking the positions of the survey stations. They are made-up of hard timber. They are made 2 to 4 cm square or 2 to 5 cm diameter and 15 to 20 cm long, tapered at the bottom end. They are driven into the ground with the help of a wooden hammer (Mallet) and kept projected about 5 cm above the surface of ground

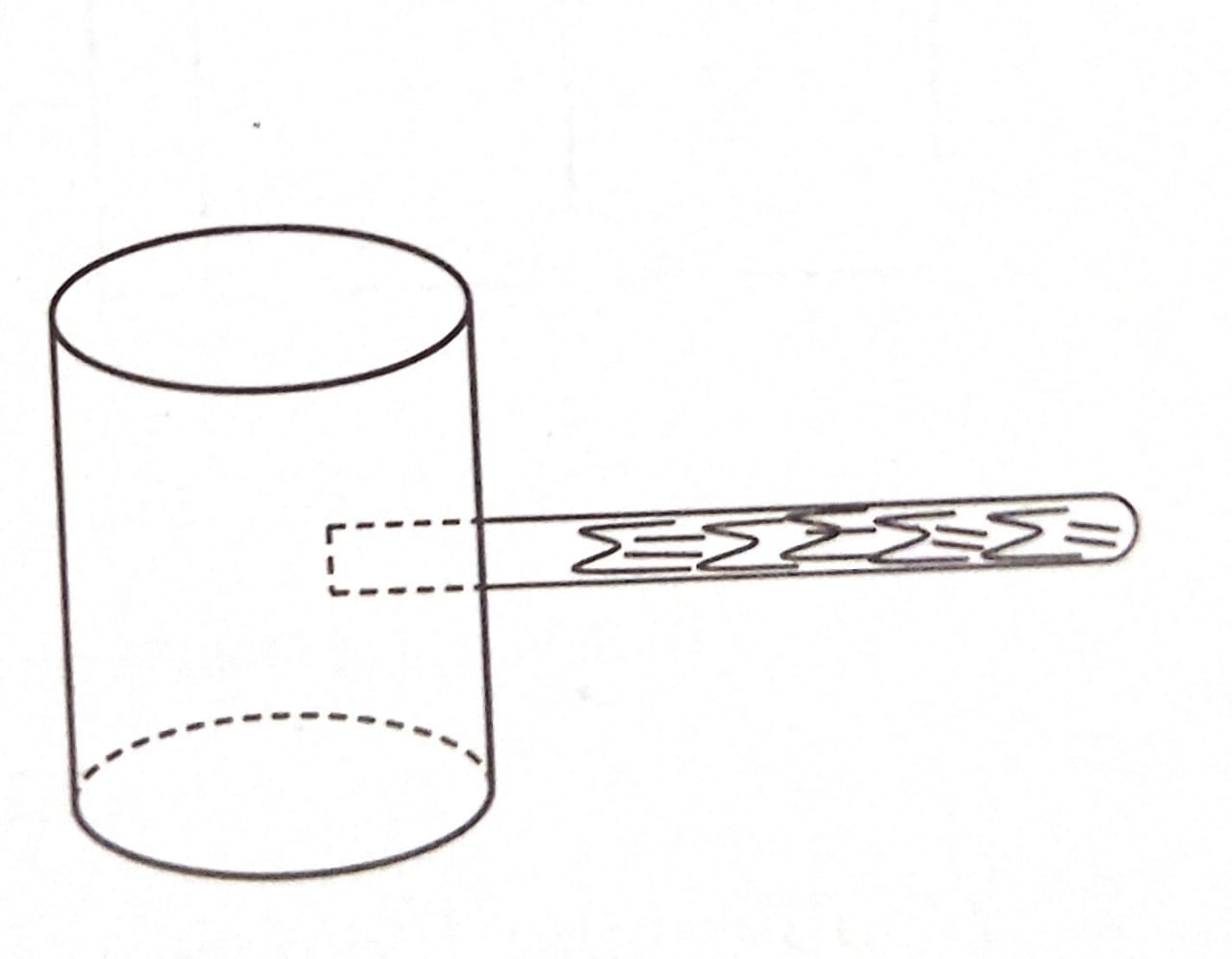

MALLET:

Mallet or wooden hammer generally used in carpentry work, is used for driving pegs into the ground. It is made from hard wood 8 to 10 cm in diametre.

FIELD BOOK:

The book in which the survey work is recorded by measurements and sketches is called survey field book. It is rectangular book of size 250 mm x 120 mm and it opens length wise. It should be made with good quality paper, well – bound and of convenient to put in pocket. There are two types of the field books.

1. Single line field book.

2. Double line field book.

1. Single Line Field Book: In this book a single line in ted in is ruled in the middle of the each page. This line represent the chain line or survey line, the chainage distances were writte along the line and the offsets were recorded in the book or either side i.e., left or right of the line. This book is mos convenient for large scale work, involving much detaile dimensions

2. Double Line Field Book : This is similar to single line field book in size. In this field book two lines with red color are marked at middle of page a bout 15 mm apart. The distance along chain line are written within the double line, as it represents chain or survey line. It is most commonly used for ordinary work